Latest Test and Measurement News

Highly flexible multi-axes X-Ray Inspection System

Highly flexible multi-axes X-Ray Inspection System

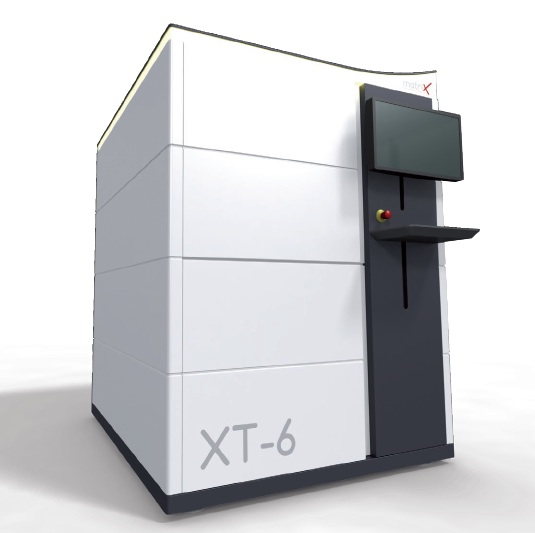

18 October 2013 – MatriX Technologies, German manufacturer and worldwide supplier of automatic and manual X-Ray inspection systems (AXI & MXI) for quality assurance in industrial production, presents its new inspection concept setting new standards in inspection part manipulation. The patented hexapod-manipulator realizes detailed, extreme X-Ray transmission angles in the smallest of space with maximum speed.

As the concept supports universal sample trays, it allows for inspection of electronic components (e.g. double-sided PCBs) and complete modules as well as casting parts and medical implants. Optionally, the XT-6 can be equipped with an automatic load/unload or for CT configuration.

The new XT-6 concept allows free and flexible movements on all axes based on a parallel-kinematic hexapod manipulation unit. The six axes motion unit can be moved flexibly with one hand via space mouse navigator in vertical and horizontal direction and around 180°. As moving mass and axes are reduced to a minimum, this innovative technology is highly dynamic and precise. It’s mainly applicable for high-quality transmission and material analysis of inspection parts with different transmission angles needed.

The standard system setup is suitable for inspection dimensions up to 400x400 mm, an XL configuration for up to 550x550 mm is optional. The XT-6 can be equipped with different X-Ray tubes up to 160 kV and state-of-the-art detectors. The system provides up to 4 X-Ray images per second in transmission mode.

Because of its compact size, flexibility and high-resolution visualization, the XT-6 is useful for laboratory X-Ray inspection as well as for automatic small series production. Analysis results are generated with the proprietary, industry proven MIPS software platform with interfaces to all MIPS modules: MIPS_Analyser (MXI tool for image analysis), MIPS_Inspect (AXI with automatic defect detection) and MIPS_Verify (for external defect image verification and process control). Therefore, the complete MatriX algorithm library for automatic analysis is applicable for automatic solder joint inspection like BGA head-in-pillow inspection, THT/PTH Barrel-fill measurement or void analysis for casting parts.

Furthermore, the system is available with a Planar CT reconstruction setup and an efficient visualization software. As the test object is always transmitted in the focal-spot center even at extreme angles, the XCT-6 provides high-resolution 3D slice images. Another interesting option is automatic load/unload with an in/out shutter system. Together with the XT-6 MatriX offers specified, customized solutions for automatic inspection processes.

www.m-xt.com/